Materials for belt conveyor service

We supply tested products for servicing, from high-quality glues to mechanical quick-fasteners or belt maintenance materials. Our range of repair products is based primarily on gluing rubber, but we also supply tested materials for quick belt repair using mechanical joins. In the case of standard service we primarily emphasize quality, speed, and simplicity. Aside from repairs themselves, we also provide technical consulting.

Gluing for Belts

We offer service materials including vulcanizing presses. We supply tested single-component and dual-component glues for both cold and hot application characterized by high adhesion, quality, universal use, and easy storage.

Advantages:

- universal use and high adhesion

- easy storage and long life

- cost savings and environmental protection due to waste reduction

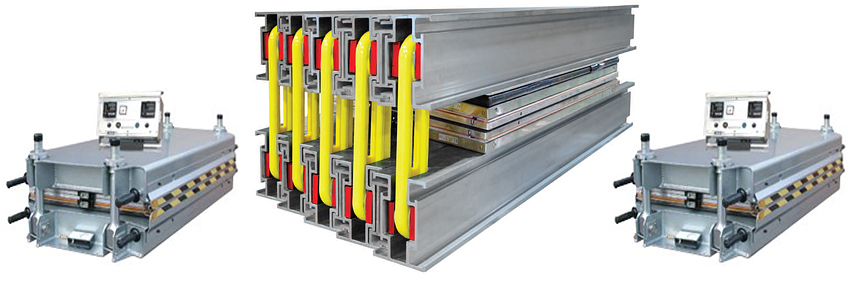

Vulcanizing presses

for effective repairs, we supply a broad range of high-quality portable vulcanizing presses for bonding conveyor belts of various widths, including versions with cooling.

Glues

we supply high-quality glues for cold and hot bonds, including single-component and dual-component glues as well as glues for repairing damaged belt surfaces. The advantages of our glues include tube packaging, thanks to which the glue can be applied directly to the surface and then sealed, allowing any unused glue to be used up later, as opposed to glue packaged in cans.

Rubber coatings

to improve the coefficient of friction between the conveyor belt and conveyor rollers and to ensure adhesion even under wet and dirty conditions. Profiled rubber slows rollers down.

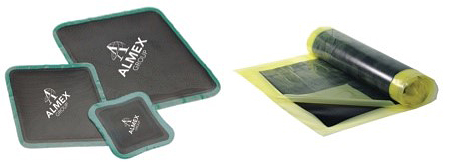

Belt maintenance

strips of self-adhesive repair rubber for cold repairs, for belts with a textile carcass and with steel cords

Belts with a smooth surface and adhesive bottom surface – use of this material extends system life and maintenance intervals. Uses: speed reduction for non-drive drums, abrasion-resistant liner, corrosion-resistant liner.

Mechanical Joins for Textile Belts

As opposed to gluing, mechanical joins have the advantage of simple and quick repair. They are only used for textile conveyor belts where the strength of the join is comparable with the strength of glued joins. Our joins have a clear advantage due to their high quality and quick application. We offer several types of quick-fasteners for various applications. All mechanical joins are packaged in special cardboard packages that are tear-resistant even when dropped.

Advantages:

- Quick and easy installation, for example to repair a cut belt

- KROT and 35-50-65 technology requires no pre-drilling

- Joins from hardened steel and for aggressive environments

- Excellent mechanical properties through the use of high-strength steel alloys and plating with white zinc with zero chrome content

Types of mechanical joins:

KROT and KROT R mechanical fasteners

for joining rubber-textile conveyor belts with thickness 8 mm and up with tensile strength of up to 3000 kN/m, including belts with a high degree of surface wear. These fasteners can be installed without pre-drilling the carcass and without damaging the textile cords. Joint life under permanent operation is 2 to 4 years.

for joining rubber-textile conveyor belts with thickness 8 mm and up with tensile strength of up to 3000 kN/m, including belts with a high degree of surface wear. These fasteners can be installed without pre-drilling the carcass and without damaging the textile cords. Joint life under permanent operation is 2 to 4 years.

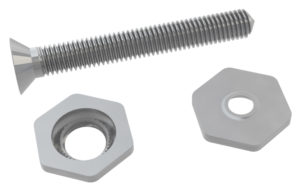

VINT mechanical fasteners

for joining rubber-textile conveyor belts with thickness 8 mm and up with tensile strength of up to 3000 kN/m, including belts with a high degree of surface wear. Joint life under permanent operation is 2 to 4 years.

for joining rubber-textile conveyor belts with thickness 8 mm and up with tensile strength of up to 3000 kN/m, including belts with a high degree of surface wear. Joint life under permanent operation is 2 to 4 years.

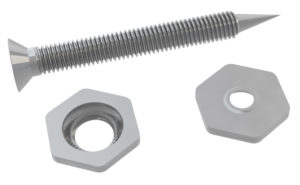

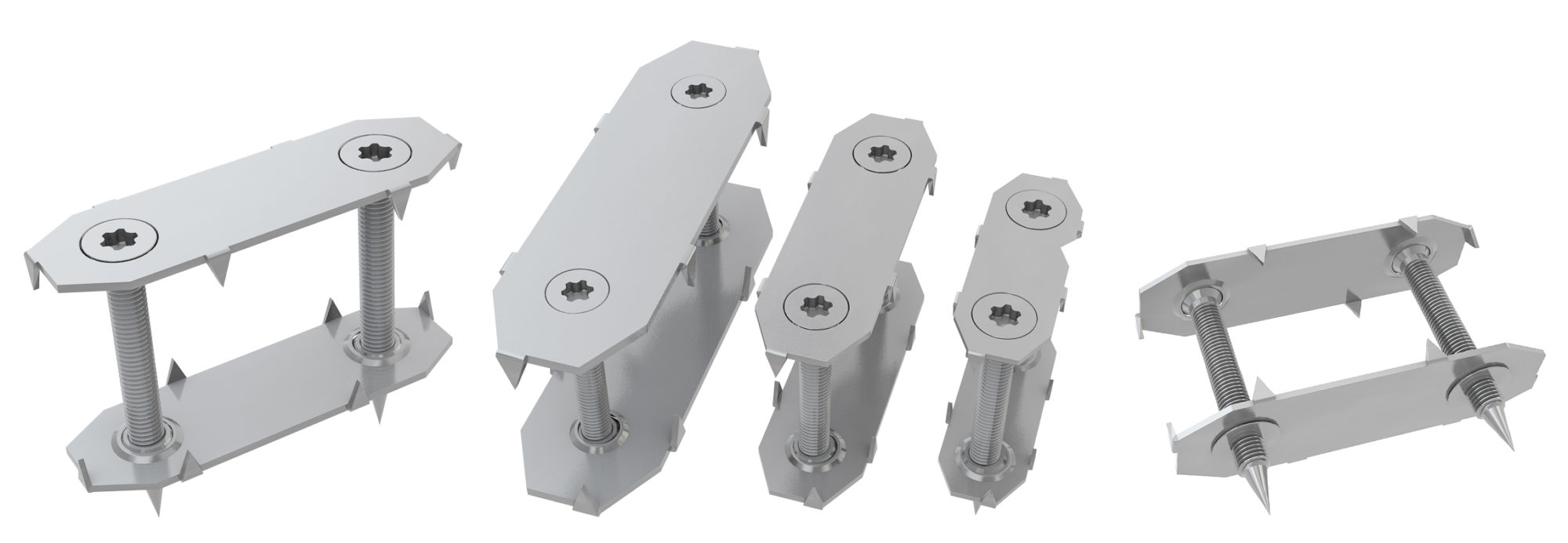

35-50-65 mechanical fasteners

for butt-joining belts, with tensile strength of up to 700 kN/m, including belts with a high degree of surface wear. Suitable for joining highly loaded belts with a split or patched join, and for repair of longitudinal and diagonal cuts. Fasteners with special screws permit installation without pre-drilling and without damage to cord fabric. They are maximally countersunk to facilitate passage over drive, end, and guide rollers. Joint life under permanent operation is 2 to 4 years. The numbers 35, 50, and 65 indicate fastener spacing.

for butt-joining belts, with tensile strength of up to 700 kN/m, including belts with a high degree of surface wear. Suitable for joining highly loaded belts with a split or patched join, and for repair of longitudinal and diagonal cuts. Fasteners with special screws permit installation without pre-drilling and without damage to cord fabric. They are maximally countersunk to facilitate passage over drive, end, and guide rollers. Joint life under permanent operation is 2 to 4 years. The numbers 35, 50, and 65 indicate fastener spacing.

RIVET mechanical fasteners

for joining rubber-textile conveyor belts with tensile strength of up to 100 kN/m, for joining longitudinal or any other cuts. Rivets are used in coal, chemical, and agricultural operations. Joint life is at least 18 months.

for joining rubber-textile conveyor belts with tensile strength of up to 100 kN/m, for joining longitudinal or any other cuts. Rivets are used in coal, chemical, and agricultural operations. Joint life is at least 18 months.