Conveyor belt accessories

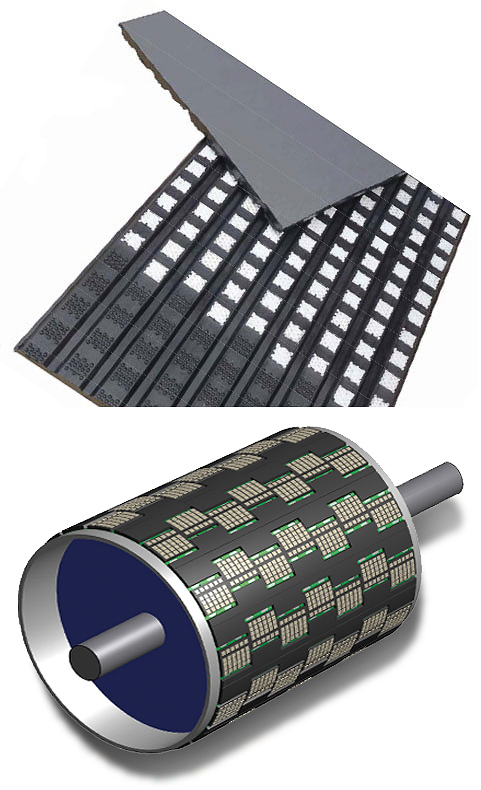

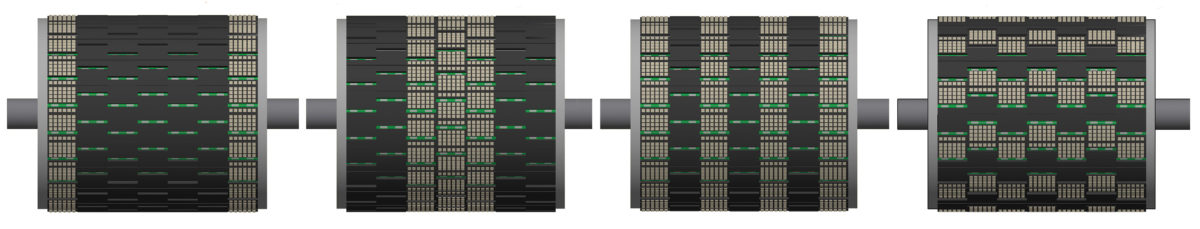

Ceramic Drum Liners

Ceramic tiles are vulcanized into rubber belts, which are welded to the drive drum, creating a surface with a high coefficient of friction, ensuring greater drive transfer from the drum to the conveyor belt. Several tile distribution patterns are available.

Ceramic tiles are vulcanized into rubber belts, which are welded to the drive drum, creating a surface with a high coefficient of friction, ensuring greater drive transfer from the drum to the conveyor belt. Several tile distribution patterns are available.

Advantages:

- Improved tension

- Eliminates belt slippage

- Reduces steel liner wear

- Reduces belt wear

- Improves water drainage from drive drums

STAR Tracker

![]() High performance self centerer by proportional and continuous action.

High performance self centerer by proportional and continuous action.

- Works flat or troughed

- Equiped with an anti-clogging skirt

- Equiped with retaining locks for idlers

- Large variety of idlers quality

- Strong structure, reinforced version available

- Works head down on chevron belts

- Symmetrical: centering belts with double direction of flow

- Economic by only replacing idler in a few minutes

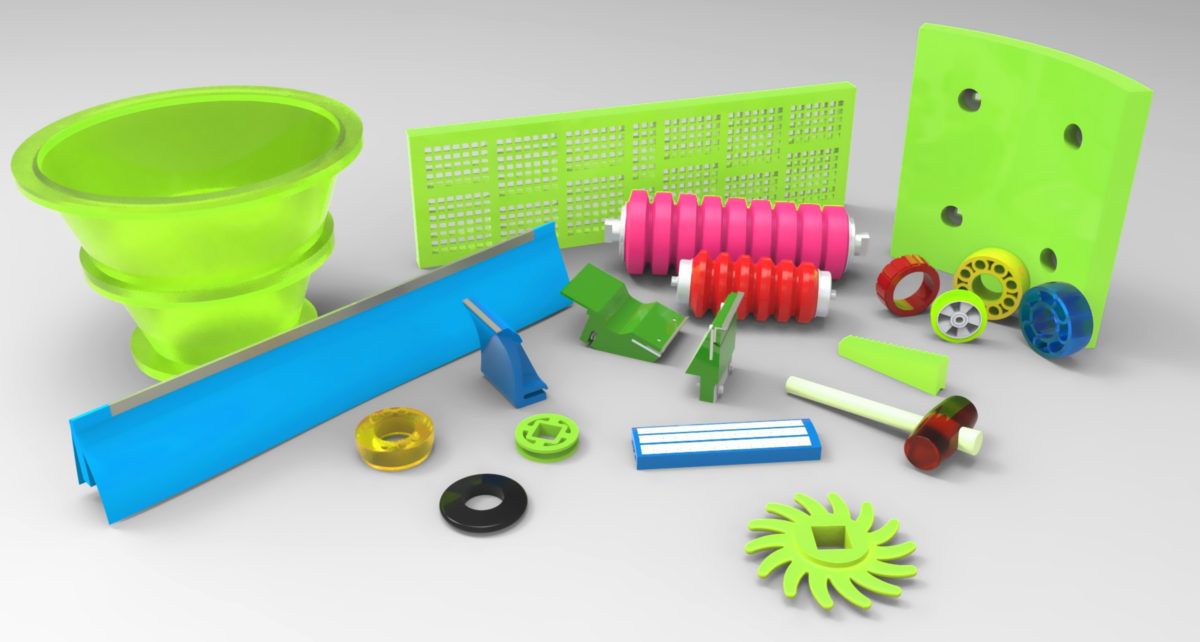

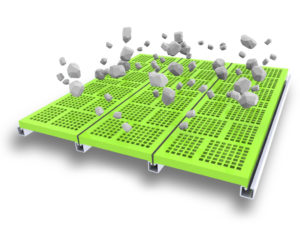

Polyurethane accessories

High-quality accessories made of polyurethane, different variants. For example screens and technical parts.

High-quality accessories made of polyurethane, different variants. For example screens and technical parts.

- Protects against corrosion, abrasion

- High chemical resistance

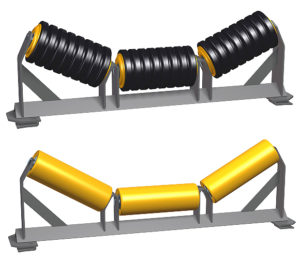

Conveyor Rollers

We supply a broad range of conveyor rollers, including special types for extreme environments, heavy loads, and high-speed conveyance. We have smooth, reel, guard, disc, spiral, or rubberized rollers.

We supply a broad range of conveyor rollers, including special types for extreme environments, heavy loads, and high-speed conveyance. We have smooth, reel, guard, disc, spiral, or rubberized rollers.

Advantages:

- High quality and long life

- Reduced belt wear

- Custom manufacture

- Rollers for extreme conditions and demanding operations

Belt Conveyor Stations

We supply two basic types of belt conveyor stations:

We supply two basic types of belt conveyor stations:

Profile stations welded from flat and angle iron sections for belt widths from 400 to 1400 mm. Stations are suitable for conveyors made with U-profiles, and are mounted on the conveyor frame using holders – no drilling required.

Pipe stations for belt widths from 1000 to 2000 mm, which are located between structural elements to keep the belt running on-axis. The stations are installed on the conveyor frame using nuts and bolts. Pipe stations are especially suitable for extremely demanding operating conditions. Upon special request we can also manufacture and deliver specially designed stations for extreme climactic conditions and specific loads.

Station types:

- Belt conveyor load-bearing systems

- Belt conveyor return systems

- Load impact systems

- Stand-along systems

- Self-cleaning systems

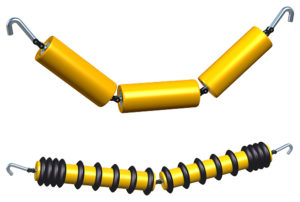

Garlands

We supply load-bearing garland stations with a hook for various belt parameters and uses.

Safety Trip Wires

Trip wires along the entire conveyor belts are used to immediately stop the belt from any location in case of need. This simple safety element can prevent costly damage caused by delayed response.

Magnetic Metal Separators

Our magnetic systems have a specially-shaped magnetic field that ensures sufficient power even at significant distances from the surface of the separator. We supply various separator types, for example: suspended permanent magnetic separators, permanent magnetic drums, separators for non-ferrous metals, magnetic filters, tube magnets, flow-through separators, rotating bar magnets, and cascade separators.

We supply three basic suspended permanent separator types:

- static type — without a cleaning strip, in cases where iron items are rare

- self-cleaning type — suspended at the end of the conveyor belt

- longitudinal self-cleaning type — placed at the end of the conveyor belt